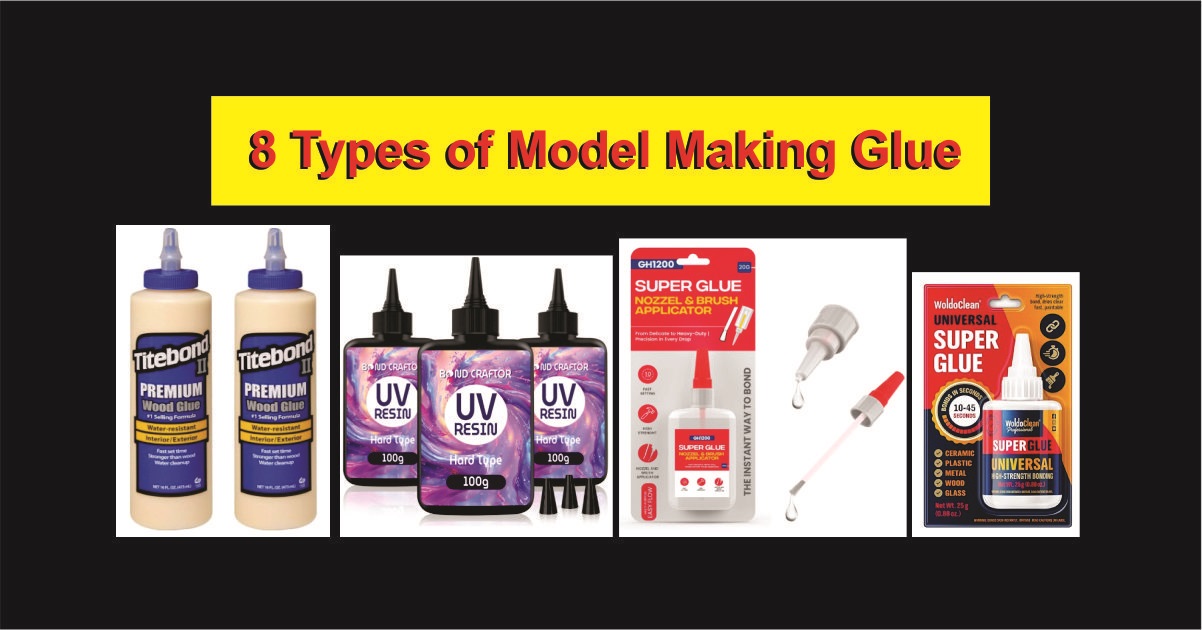

Here’s a description of various Types of Model Making Glue and their properties, operation times, and pros and & cons:

1. Cyanoacrylate (CA) Glue

– Properties: Fast-drying, high-strength, and waterproof.

– Operation Time: Instant bonding, fully cured in 1-5 minutes.

– Positive Sides: Fast bonding, high strength, and suitable for plastics, metals, and woods.

– Negative Sides: Brittle, prone to cracking, and may damage certain materials.

2. Epoxy Resin Glue

– Properties: Two-part mixture, high-strength, and resistant to heat and chemicals.

– Operation Time: Mixing time: 5-10 minutes, curing time: 5-24 hours.

– Positive Sides: High strength, durable, and suitable for metals, woods, and plastics.

– Negative Sides: Slow curing, requires mixing, and can be messy.

3. Acrylic Glue

– Properties: Water-based, flexible, and suitable for plastics, woods, and fabrics.

– Operation Time: Drying time: 5-30 minutes, fully cured in 1-24 hours.

– Positive Sides: Flexible, easy to clean up, and suitable for various materials.

– Negative Sides: Lower strength compared to other glues, may not be suitable for heavy loads.

4. Polyurethane Glue

– Properties: Moisture-curing, flexible, and suitable for woods, plastics, and metals.

– Operation Time: Drying time: 5-30 minutes, fully cured in 1-24 hours.

– Positive Sides: Flexible, suitable for various materials, and resistant to moisture.

– Negative Sides: May foam during curing, requires moisture to cure.

5. Hot Melt Glue

– Properties: Thermoplastic, fast-drying, and suitable for plastics, woods, and fabrics.

– Operation Time: Instant bonding, fully cured in 1-5 minutes.

– Positive Sides: Fast bonding, easy to apply, and suitable for various materials.

– Negative Sides: Limited strength, may not be suitable for heavy loads or high-temperature applications.

6. Chemical Solvent Glue

– Properties: Liquid chemical solvents, fast draying suitable for various plastic sheets.

– Operation Time: Instant bonding, fully cured in 1 minute.

– Positive Sides: Fast bonding, easy to apply, and suitable for various plastic. it melts plastic and welds firm joint.

– Negative Sides: Hazardous Chemical for operation. it dries quickly so need to take proper amount of liquid in brush

7. White Glue (PVA Glue)

– Properties: Water-based, flexible, and suitable for papers, fabrics, and woods.

– Operation Time: Drying time: 5-30 minutes, fully cured in 1-24 hours.

– Positive Sides: Easy to clean up, flexible, and suitable for various materials.

– Negative Sides: Lower strength compared to other glues, may not be suitable for heavy loads.

8. Silicone Glue

– Properties: Flexible, waterproof, and suitable for metals, plastics, and woods.

– Operation Time: Drying time: 5-30 minutes, fully cured in 1-24 hours.

– Positive Sides: Flexible, waterproof, and suitable for various materials.

– Negative Sides: May not be suitable for high-temperature applications, can be messy.

When choosing a glue, consider the specific materials you’re working with, the desired strength and flexibility, and the operation time. Always follow safety precautions and instructions for use.